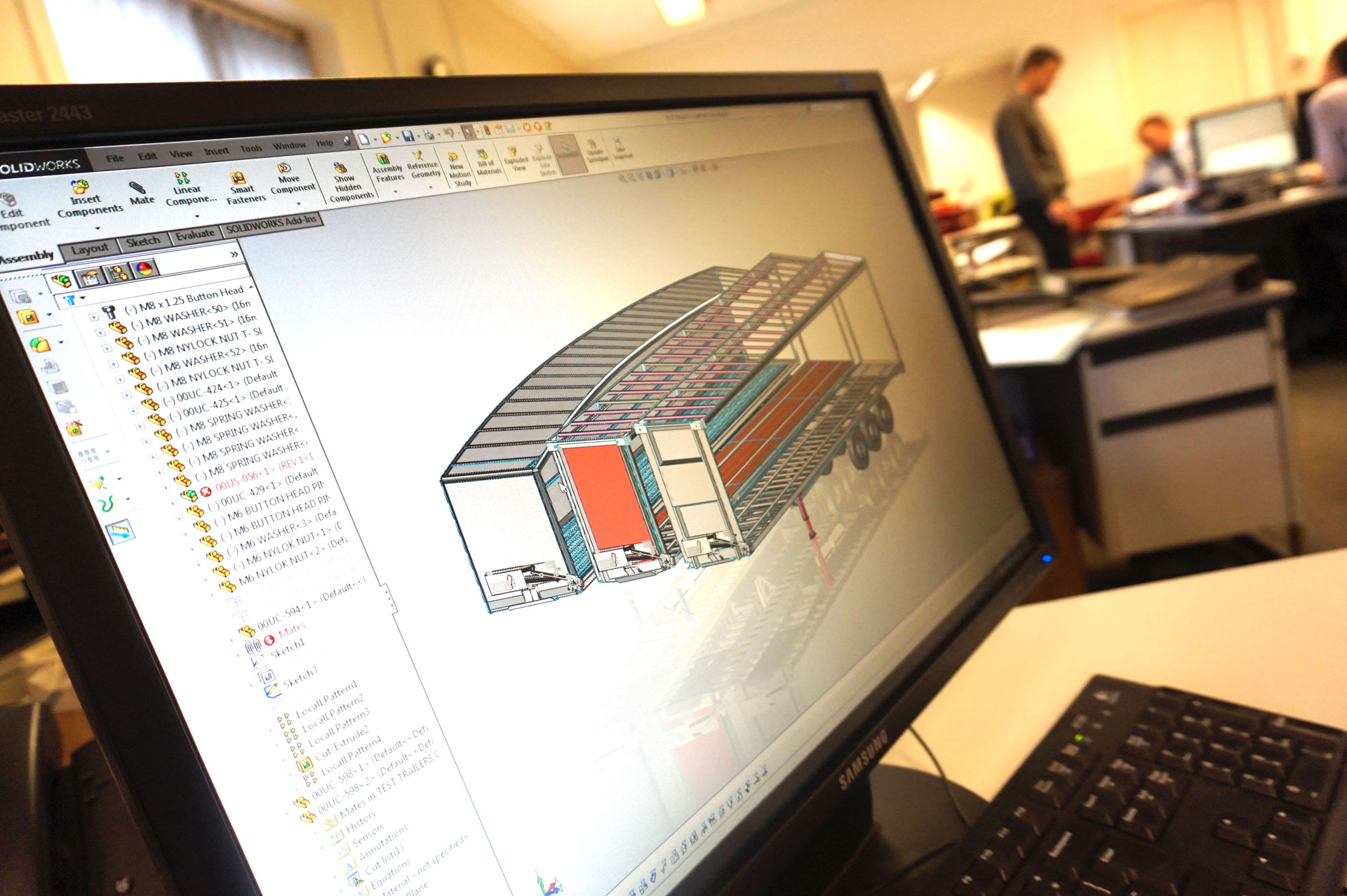

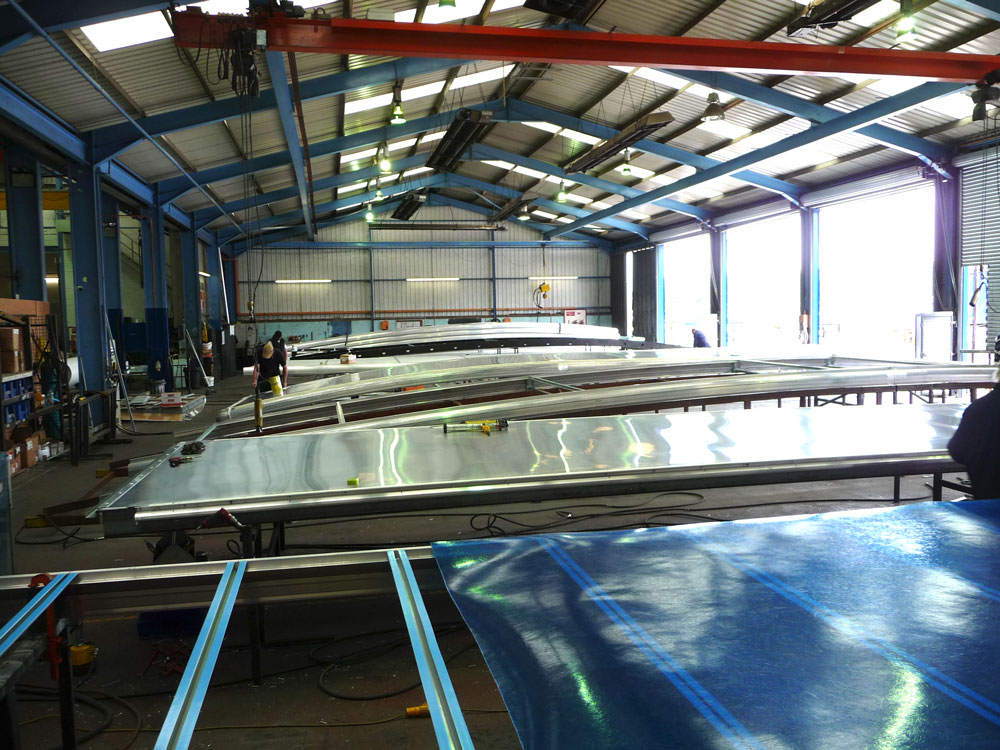

Uniquely, Don-Bur manufacture and finish the entire product in-house.

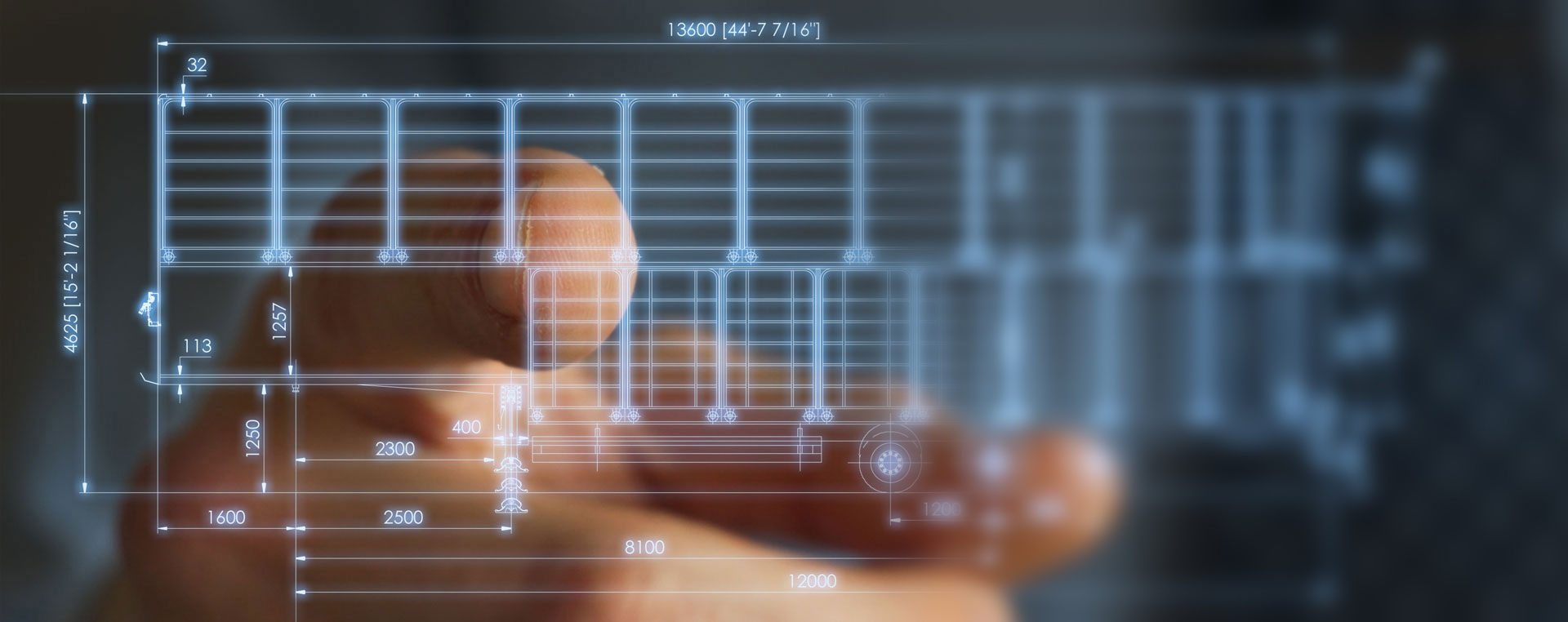

From the outset, we assume total responsibility for optimisation, suitability and durability. In our view, these three key factors embody the term "value" and every client we have demands nothing less.

The "one-stop-shop" ethos gives the customer peace of mind, knowing that Don-Bur has total accountability.

We’d love to hear from you – get in touch today!