Increase Trip Capacity with High Cube Double Deck Trailers

What Are Double Deck Trailers?

Double Decks are designed to give you twice the carrying capacity of a standard single deck, reducing your number of trips and associated costs by half.

They are now commonplace in the transport industry and are predominantly used for the trunking distribution of light/medium weight goods.

We’d love to hear from you – get in touch today!

Features

No company has more experience in the manufacture of Double Deck trailers than Don-Bur and their trailers now dominate the major UK fleets.

- Heavy duty construction

- Fixed, Ratchet & Lifting Deck + Tail-lifts to suit requirements

- Industry-leading 52 UK pallet capacity (13.6m long). Up to 60 UK Pallets on Longer Semi Trailers

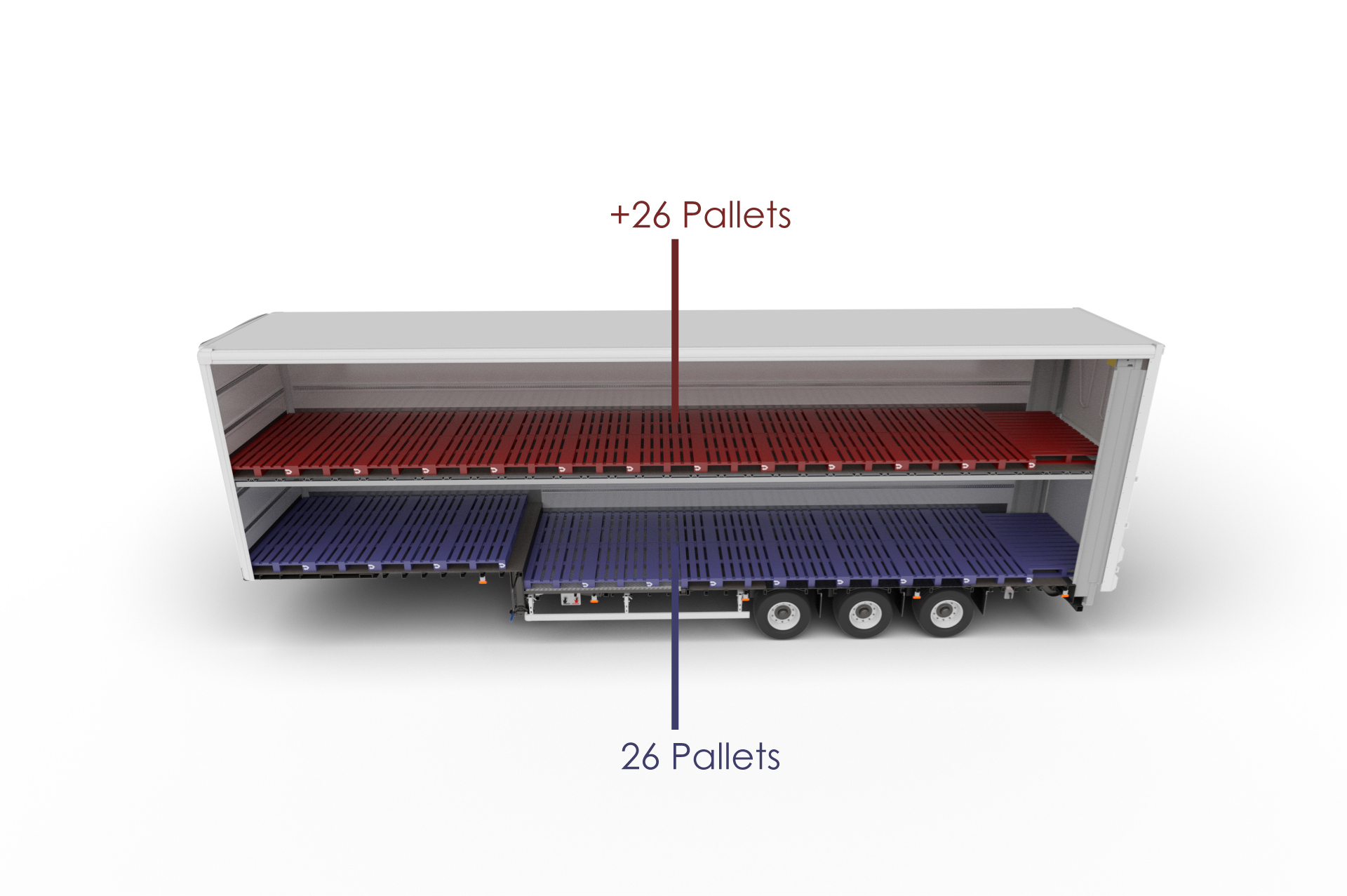

100% Capacity Increase

With a potential increase of up to 100%, Don-Bur's Double Decks can provide operators with a 52 UK pallet carrying capacity, which is an additional 26 UK Pallets when compared to a standard 13.6m long single deck trailer.

This can reduce the number of deliveries by 50%.

Fixed Second Deck

Don-Bur's fixed Double Decks have static double decks positioned at a height to suit your payload.

- Box or curtain sided

- 3/4 or full-length deck

- Standard or mesh type 2nd deck

- EcoStream Fuelsaver roof (average ~15% saving)

Lifting Second Deck

Lifting Decks (hydraulically powered) have become increasingly popular at the bay due to the speed and flexibility of loading. A full deck can be loaded completely before lifting to an upper position and loading underneath.

Ratchet Second Deck

The variable height Ratchet Double Deck system is designed and manufactured exclusively by Don-Bur. (Registered Design 2001). Ratchet Decks are a forklift operated, multi-positional, mechanical moving deck system for curtain sided trailers.

Urban Double Deck Trailers

Urban Double Decks are becoming more and more commonplace in cities as operators try to increase the efficiency of their fleet. Don-Bur offers a number of Urban solutions to suit your requirements

- Box | Curtain | Straight Frame | Step Frame

- Lifting, Ratchet & Fixed Deck options

- City-Safe & City-Quiet options available

Wedge Bodywork

Don-Bur 'Wedge' Double Deck trailers provide operators with straight flat floor spans (no step) on both decks, capable of achieving deck clearances of up to 1928mm (6' 4") and a 52 UK pallet capacity on all types.

Special Types

Don-Bur manufactures a variety of double deck solutions to cater for specialised operations.

- Independent Suspension | Drop-Frames

- Butterfly Decks | Revolving Decks | Removable Decks

Published: Thu 25 Jan 2024 (Edited: Fri 21 Mar 2025)