Lifting Deck Trailers : High Volume & Fast Loading

Your Design For Your Needs

No company has more expertise in the specialist design and build of hydraulic Lifting Deck trailers (Sometimes referred to as moving deck trailers) than Don-Bur.

Their experience with Lifting Deck trailers extends back to the 1980's and their Lifting Deck range of products now dominate the major fleets. Don-Bur consistently produces what is arguably the best and most cost effective hydraulic system technology in the industry.

We’d love to hear from you – get in touch today!

What Are Lifting Deck Trailers?

Double Deck trailers are now commonplace; especially in trunking operations. However, the time to load a double deck is limited by the equipment needed to lift the load to the second deck level.

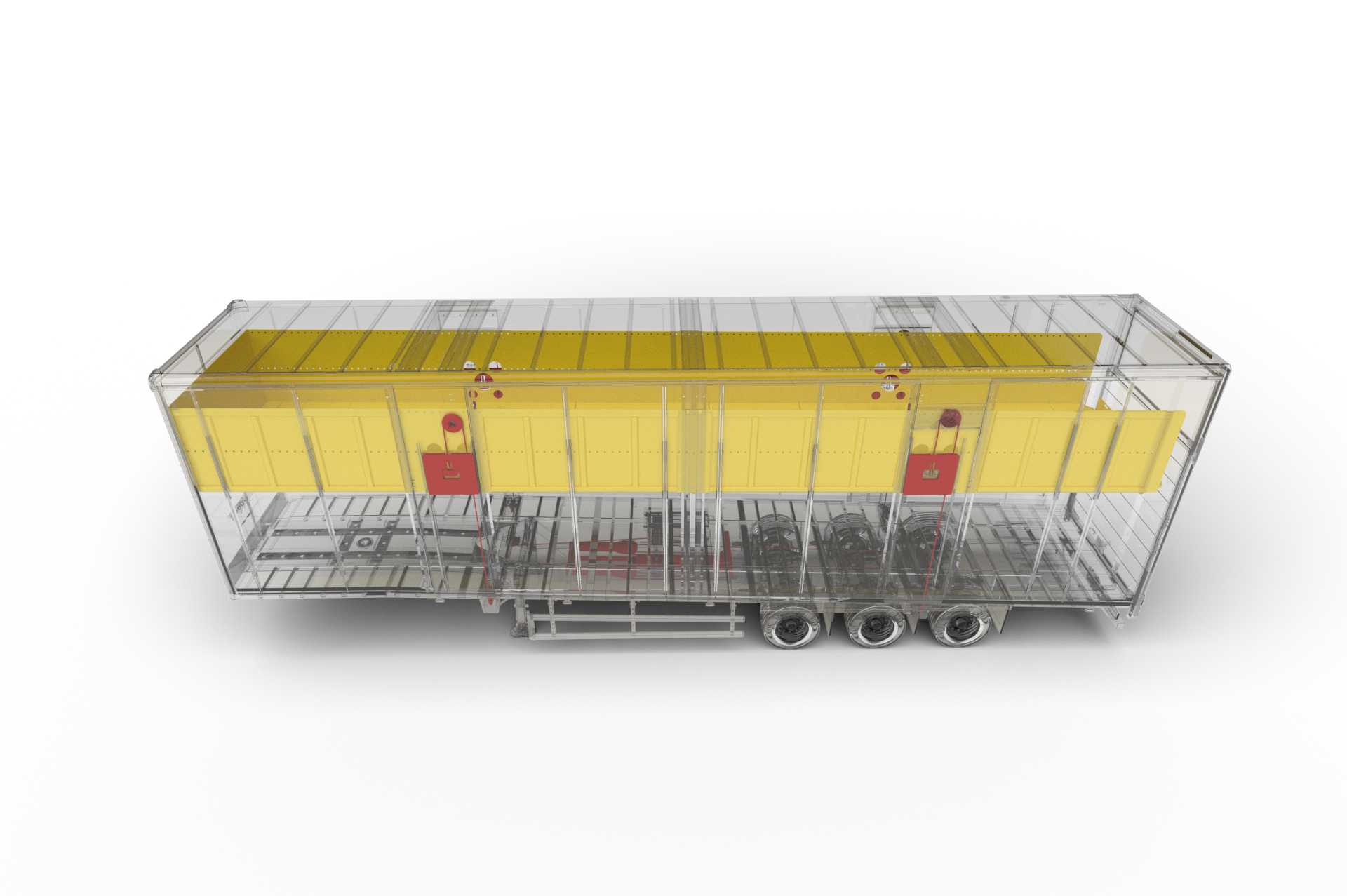

A Lifting Deck is a full length or rear 3/4 length deck which can be loaded at normal deck height. Pressing a button will lift the entire deck (and load) up, and out of the way, permitting a second full-length payload to be posititioned on the lower deck.

This means the fast loading for the payload equivalent of two trailers.

Features

Whatever your needs, Don-Bur can engineer a solution to meet your operational and budgetary needs.

- Durable construction

- Straight | Step-frame

- Industry-leading 52 UK pallet capacity

- Tail-lifts to suit requirements

- High Cube ~120m3

- Fast Loading/Unloading at Bay

Single Ram & Pulley System

Don-Bur's proven single ram and pulley system generates a consistent, uniform lift which is unaffected by varying load weights on various parts of the deck and is less susceptible to the stressing and flexing of the trailer.

52 UK Pallet Capacity

Don-Bur's Lifting Decks were the first in the industry to offer a 52 UK pallet carrying capacity.

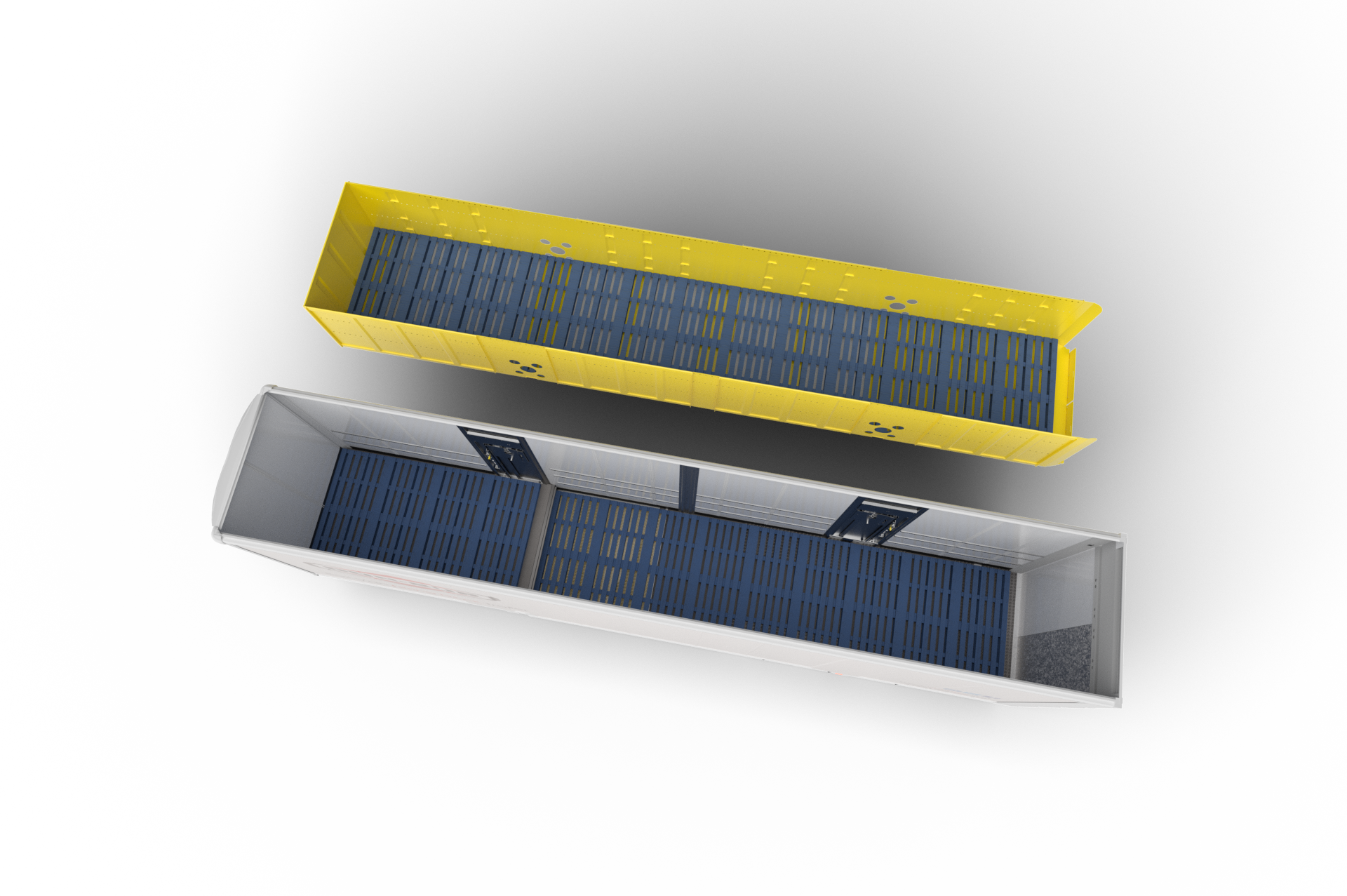

When specified with Don-Bur's 7.5mm thick 'Blade' panel, operators can achieve a deck width of 2440mm across the entire length of the Lifting Deck tub, which is sufficient to carry 26 pallets on each deck.

Wedge Lifting Decks

Don-Bur 'Wedge' Lifting Deck trailers provide operators with full height loading on both decks, capable of achieving deck clearances of up to 1928mm (6' 4") and a 52 UK pallet capacity on all types.

Temperature Controlled Lifting Decks

This 3d video example highlights the construction and benefits of Don-Bur frozen/chilled double deck trailers.

Enhanced Safety Features

To ensure the highest levels of safety, our lifting deck trailers incorporate multiple fail-safe mechanisms designed to eliminate the risk of unintentional lowering of the deck. These safety systems include:

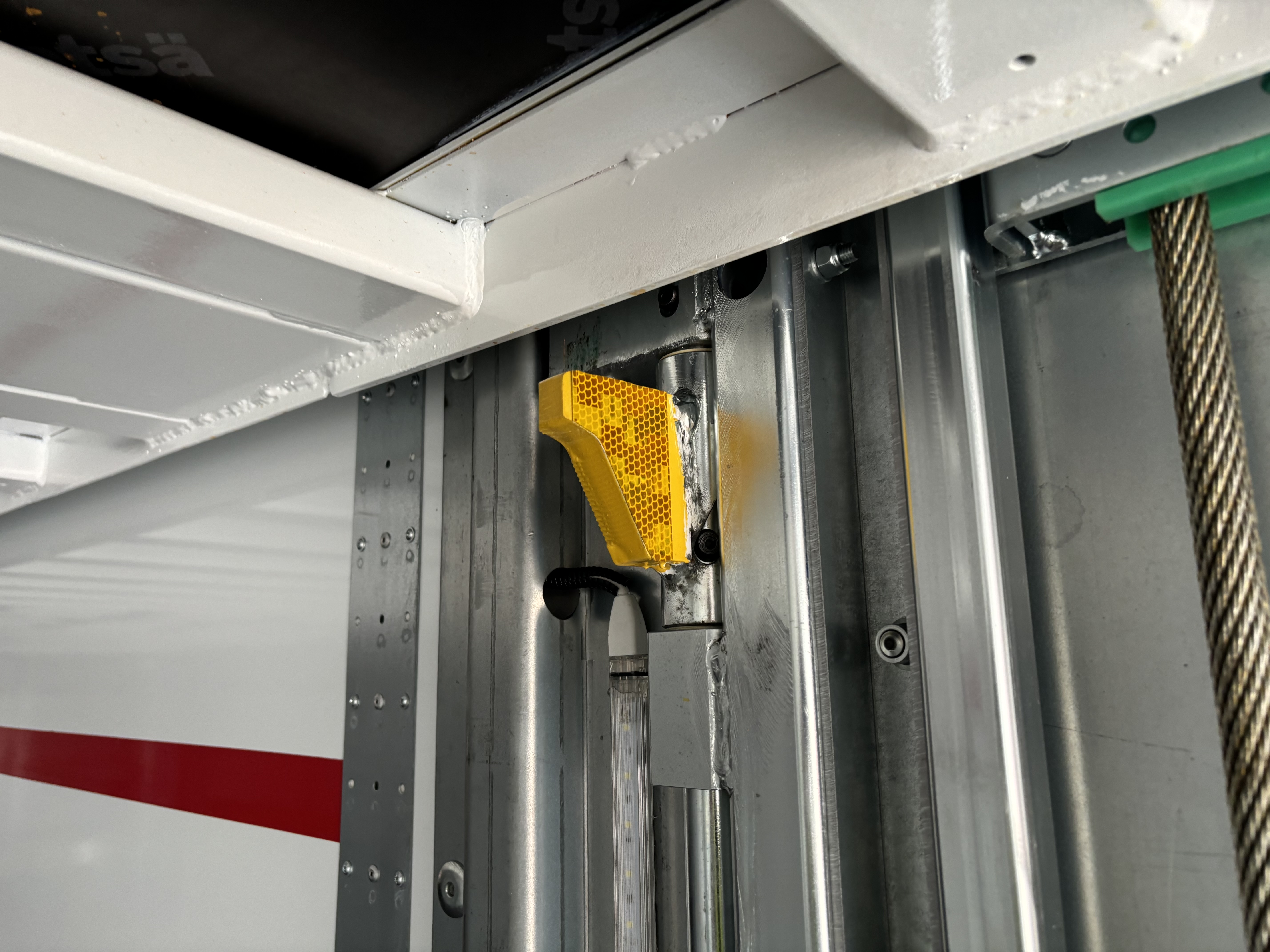

1. Rope Arrest / Brake Bar Mechanism

Each column slide plate is equipped with a robust, sprung-loaded horizontal brake bar. A vertical steel bar runs through this brake bar, and in the unlikely event that the deck loses lift support from the ropes, the brake bar automatically twists against the vertical bar. This creates a powerful jamming action, locking the deck securely in place within a drop of 50mm (incl. 25% FOS).

2. High-Strength Support Cables

The lifting system relies on 4/6 steel fibre cables, each with a remarkable strength capacity of up to 20,897 kg. This ensures that even under significant loads, the support system maintains complete structural integrity.

3. Hydraulic Burst Valve

To protect against hydraulic failures, the system features a burst valve. This valve automatically locks down the hydraulic circuit if a pipe bursts, preventing any unintended movement of the deck.

4. Sprung-Loaded Safety Paddle Locks

When the deck is in a raised position, four sprung-loaded safety paddle locks engage beneath the deck. These additional physical stops provide another layer of protection, ensuring the deck remains firmly in place.

5. Flow Control Valve

This valve limits the amount of hydraulic fluid flow, and therefore the lowering speed of the deck.

By combining these safety measures, our lifting deck trailers provide reliable and secure operation, offering peace of mind for operators and enhancing workplace safety.

Published: Fri 26 Jan 2024 (Edited: Fri 23 May 2025)