Air Supply and Brake Circuits

HGV trailers in the UK and EU use a pneumatic (air) braking system, where compressed air is supplied from the tractor unit via two airlines:

- Red Line (Emergency Line)

- Recharges the trailer’s air reservoirs and releases the spring brakes when sufficient pressure is achieved.

- If disconnected, the trailer enters an emergency braking state.

- Yellow Line (Service Line)

- Transmits the driver’s braking demand to the trailer’s relay valve, regulating brake force.

- The more the driver presses the footbrake, the greater the air pressure applied to the service brake chambers.

Key Components of the Trailer Braking System

HGV trailers feature a dual-braking system, consisting of both the service brake system (yellow airline) and the spring brake system (red airline & park brake control).

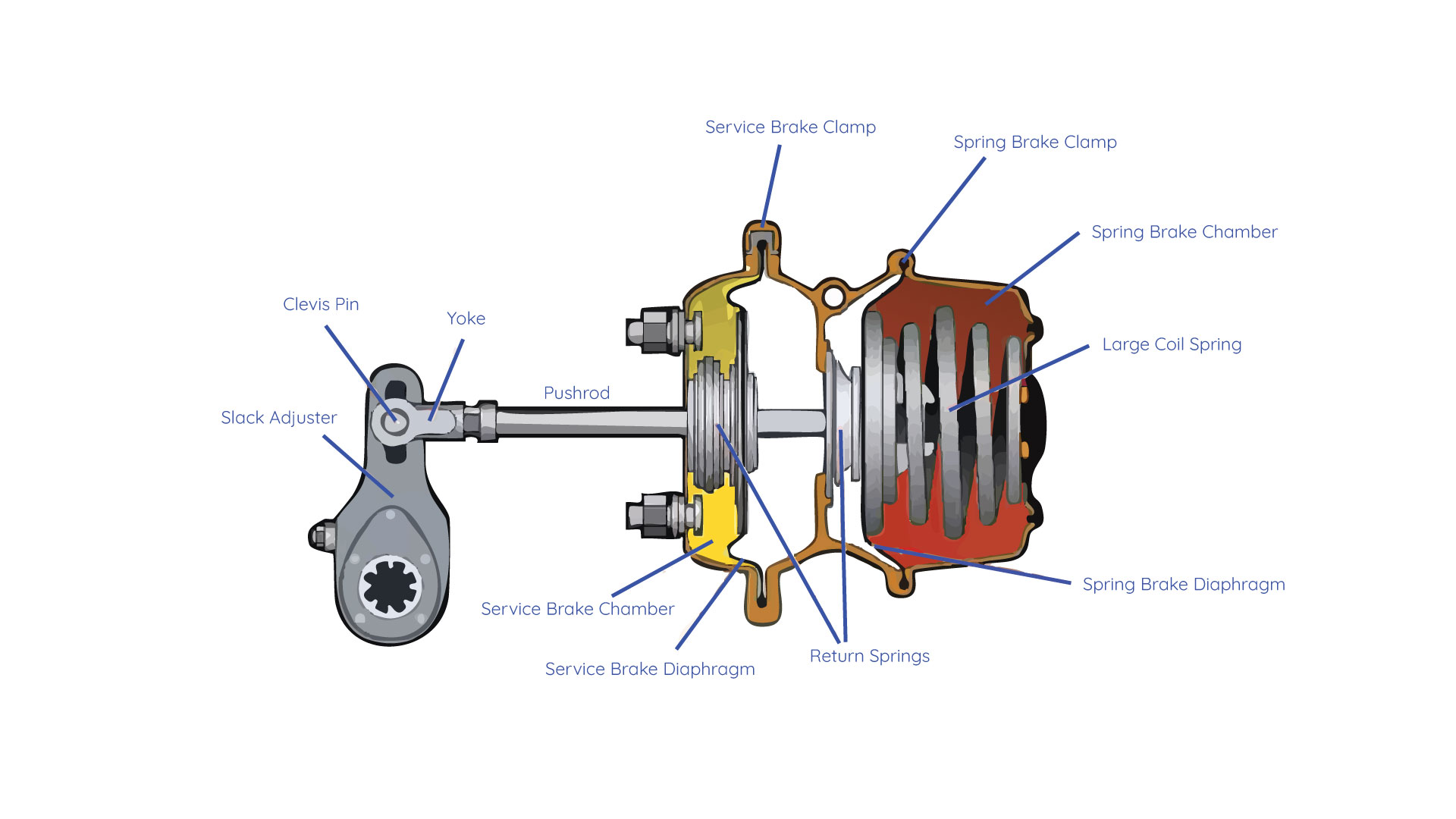

1. Dual-Chamber Brake Actuators (Spring Brake & Service Brake)

- Service Brake Chamber (Controlled by the Yellow Line)

- Applies braking force in response to footbrake pressure.

- Air pressure moves a diaphragm inside the actuator, applying the brakes proportionally.

- When the driver releases the footbrake, the air exhausts, releasing the brakes.

- Spring Brake Chamber (Fail-Safe Parking Brake, Controlled by Air Pressure)

- Spring brakes remain disengaged as long as sufficient air pressure (~3 to 4.5 BAR, depending on system design) is maintained.

- If the trailer park brake (often called the "red button") is applied, or if air supply is lost, powerful mechanical springs apply the brakes.

2. Braking Response if the Red Airline Disconnects

When the red airline is disconnected, the trailer enters an emergency braking state to prevent uncontrolled movement. The response depends on the trailer’s braking system:

- Older (Non-EBS) Trailers: The disconnection immediately exhausts the air from the spring brake chambers, causing the powerful springs to engage and hold the brakes on.

- EBS Trailers: If the red airline disconnects but electrics remain connected, the trailer still enters an emergency braking state. Instead of instantly engaging the spring brakes, it applies the service brakes via EBS, allowing ABS and stability control to manage braking more effectively.

- Modern EBS Trailers: The ECU detects motion and determines the appropriate response:

- If stationary → Spring brakes engage.

- If in transit → Service brakes engage via EBS.

3. Air Reservoir / Tanks

Stores compressed air from the red airline to maintain system pressure.

EU Regulation 13 requires air pressure to range between 6.5 and 8.5 BAR.

4. Load Sensing Valve (LSV)

Adjusts braking force relative to trailer load to prevent wheel lock-up when empty.

On EBS trailers, this function is often electronically controlled rather than mechanically adjusted.

5. Relay Valve

Speeds up brake application by quickly directing stored air from the reservoir to the brake chambers.

6. Brake Drums or Discs

- Drum Brakes → Older, robust, cost-effective but prone to heat fade.

- Disc Brakes → Improved stopping power, better cooling, and faster response.

7. ABS (Anti-lock Braking System) & EBS (Electronic Braking System)

- ABS prevents individual wheel lock-up during heavy braking.

- EBS optimises trailer braking efficiency electronically, integrating with the tractor’s braking system for better stability and control.

8. Park & Shunt Valves

- Park Valves allow drivers to engage/disengage the trailer’s spring brakes independently.

- Shunt Valves enable shunters to manually release the spring brakes without connecting the red airline, useful for short-distance yard movements.

9. Benefits of EBS and ABS

Modern Electronic Braking Systems (EBS) and Anti-lock Braking Systems (ABS) improve safety, efficiency, and vehicle control compared to traditional air braking systems.

Benefits of ABS (Anti-lock Braking System)

ABS prevents individual wheel lock-up during braking, improving stability and control, especially in emergency situations.

- Reduces the risk of skidding by modulating brake pressure, helping prevent jackknifing and loss of control on slippery surfaces.

- Maintains steering control while braking, allowing drivers to manoeuvre more safely in sudden stops.

- Helps shorten stopping distances on wet or icy roads by preventing wheel lock-up and maintaining traction.

- Reduces uneven tyre wear by ensuring even braking force distribution.

Benefits of EBS (Electronic Braking System)

EBS is an advanced braking system that improves efficiency and responsiveness by using electronic sensors and actuators instead of purely pneumatic controls.

- Provides a faster brake response by reducing the delay between brake pedal input and trailer braking.

- Distributes braking force more evenly across all axles, improving stability and reducing brake wear.

- Works in conjunction with ABS, traction control, and electronic stability programs (ESP) to enhance overall vehicle handling.

- Automatically adjusts brake force based on the trailer’s load, reducing wear and improving braking efficiency.

- Uses less compressed air than traditional pneumatic-only systems, reducing strain on the air supply.

- Offers real-time diagnostics, allowing drivers and fleet operators to monitor brake performance and detect maintenance issues early.

How EBS and ABS Work Together

Both systems enhance braking performance in different ways:

- ABS prevents wheel lock-up, improving control and reducing skid risk.

- EBS enhances braking efficiency, reduces response time, and integrates with ABS for improved stability and control.

By working together, these technologies improve road safety, reduce maintenance costs, and increase overall vehicle efficiency, making them a key feature in modern HGV fleets.

Conclusion

HGV trailer braking systems combine pneumatic control, mechanical force, and modern electronics to ensure safety and efficiency.

- When the red airline is disconnected, the trailer enters an emergency state, engaging the brakes to prevent uncontrolled movement.

- Drivers must always ensure the trailer’s parking spring brakes (also known as the "red button") are properly engaged before coupling or uncoupling.

We’d love to hear from you – get in touch today!