GRP faced plywood has been the default panel type in the UK for decades. Despite being fairly durable, it's heavy, it deteriorates and is virtually impossible to recycle. Today, Don-Bur offers many options, but which should you choose and why? Do you specify the lightest, the stiffest, the most resilient to damage or even a recyclable option?

Understanding the merits of each panel type will help to evaluate suitability and value over the vehicle's life.

Below is a guide to commont panel types:

| Standard GRP | Omnia | Carbofont | D-B Technolite | D-B Blade | Tata Coretinium | |

|---|---|---|---|---|---|---|

| Page Link | GRP Details | Omnia Details | Carbofont Details | Technolite Details | Blade | Coretinium |

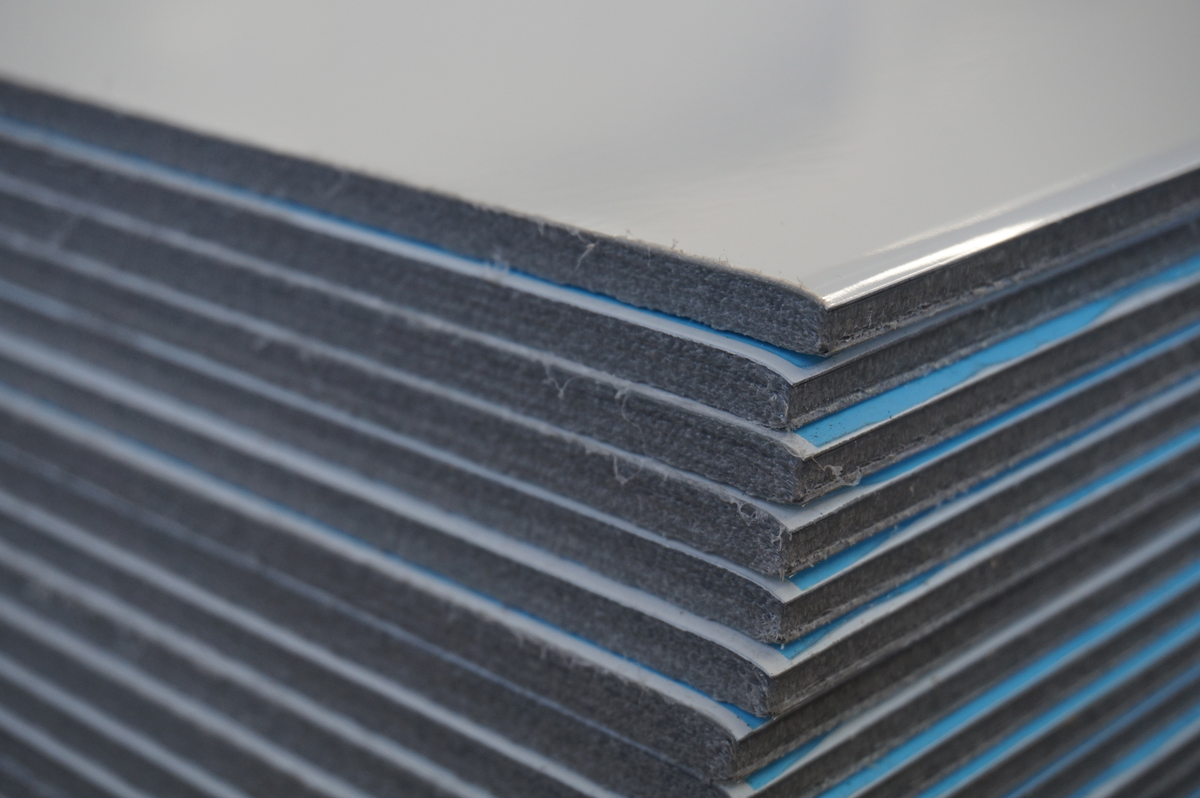

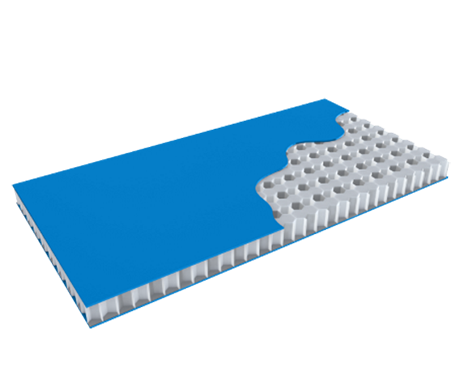

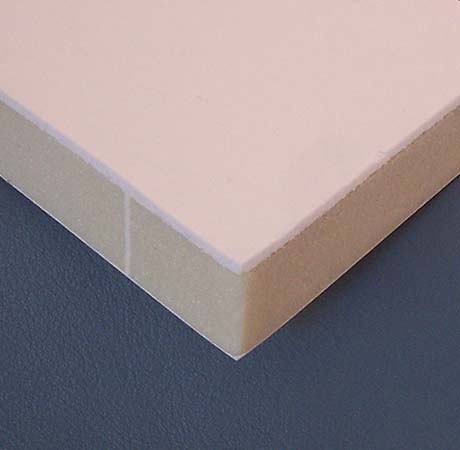

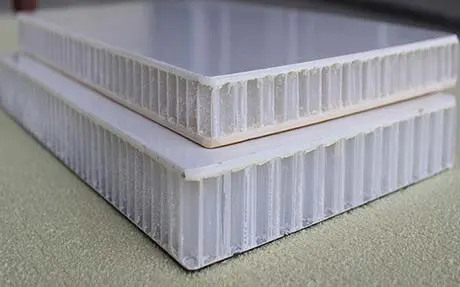

| Appearance |  |

|

|

|

|

|

| Material | Plywood/GRP | Polypropylene (PP) | GRPR/PC | Aluminium | Polyethylene (HDPE)/Steel | Polymer Plastic/ Steel |

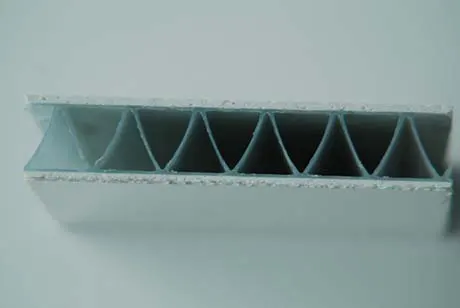

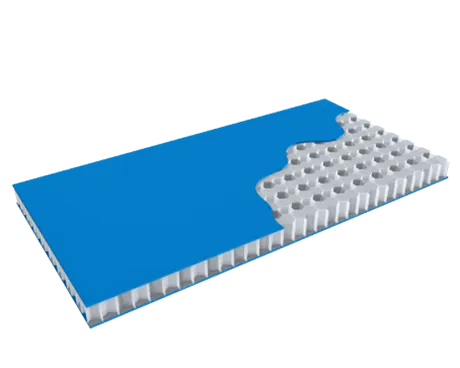

| Construction | Soft, plywood core, faced with glass reinforced plastic | Polypropylene honeycomb core faced with fibreglass reinforced polypropylene sheets | Glass Re-enforced Polyester Resin skin with Polycarbonate delta core. Gelcoat RAL 9010 finish | Aluminium honeycomb core faced with aluminium sheets | High density polyethylene (HDPE) foam core. Hot dipped galvanisation steel skin (80,000 yield hard steel). Polyester baked paint. | Rigid polymer honeycomb core faced with steel skin |

| Weight (kgs/m²) |

16 |

4.8 |

8.35 |

7.4 |

11.8 |

7.65 |

| Thickness (mm) | 20 | 30 | 20 | 20 | 7.5 | 10 |

| Surface Finish (Graphic decals have superior adhesion to smooth surfaces.) | Smooth | Dimpled | Textured | Gloss Smooth | Gloss Smooth | Smooth |

| Skin Sheet Thickness (mm) | 1 | 0.7 | 1 | 1 | 0.5 | 0.4 |

| Skin Fixation Strength |

70% |

30% |

50% |

60% |

90% |

40% |

| Rigidity Scale |

80% |

30% |

70% |

90% |

60% |

60% |

| Resistance to Crushing |

80% |

30% |

40% |

20% |

100% |

30% |

| Acute Impact Resistance Grade |

80% |

70% |

70% |

50% |

90% |

50% |

| Environmental Effect | Moisture ingress into plywood leading to eventual delamination and core deterioration. | Rigidity is affected by variances in heat. Material also affected by UV light. | Material affected by long-term UV light | NIL | NIL | NIL |

| Damage Degradation | Water ingress into plywood leading to delamination, surface deterioration and rot. | As above | As above | Subject to surface oxidisation if paint surface is broken. | Self-healing zinc skin. Subject to oxidisation if galvanised surface is broken. | Self-healing "Galvalloy" skin. Subject to oxidisation if galvanised surface is broken. |

| Flammability | Self fuelling active flame. | Self fuelling active flame. Includes glass retardant. | High heat resistance. Rated as slow burning. | Melting point 660°C | Auto-extinguishes | Classification unknown |

| Recyclability | Not recyclable |  Due to the mixture of compounds these plastic types are hard to recycle and not generally recycled in the UK Due to the mixture of compounds these plastic types are hard to recycle and not generally recycled in the UK |

De-Lamination required. Due to the mixture of compounds these plastic types are hard to recycle and not generally recycled in the UK De-Lamination required. Due to the mixture of compounds these plastic types are hard to recycle and not generally recycled in the UK |

Steel skin can be smelted. Polyethylene core is commonly downcycled in the UK Steel skin can be smelted. Polyethylene core is commonly downcycled in the UK |

Steel skin can be smelted. Polymer honeycomb core material is not classified. | |

| Absorbency | Moisture content fluctuates between 8/12% at time of milling to 30%. Trailer can fluctuate in weight by +/-240kgs | 0.03% | 0.1% | NIL | < 0.01% | NIL |

To enhance our content, some features in the Don-Bur library may include information from trusted third parties. We encourage you to perform your own research and seek additional advice before making any investment or financial decisions based on the information provided. Don-Bur assumes no responsibility for the accuracy, completeness, or timeliness of third-party information.

We’d love to hear from you – get in touch today!