New University of Surrey Study Reveals Teardrop Trailer Secrets

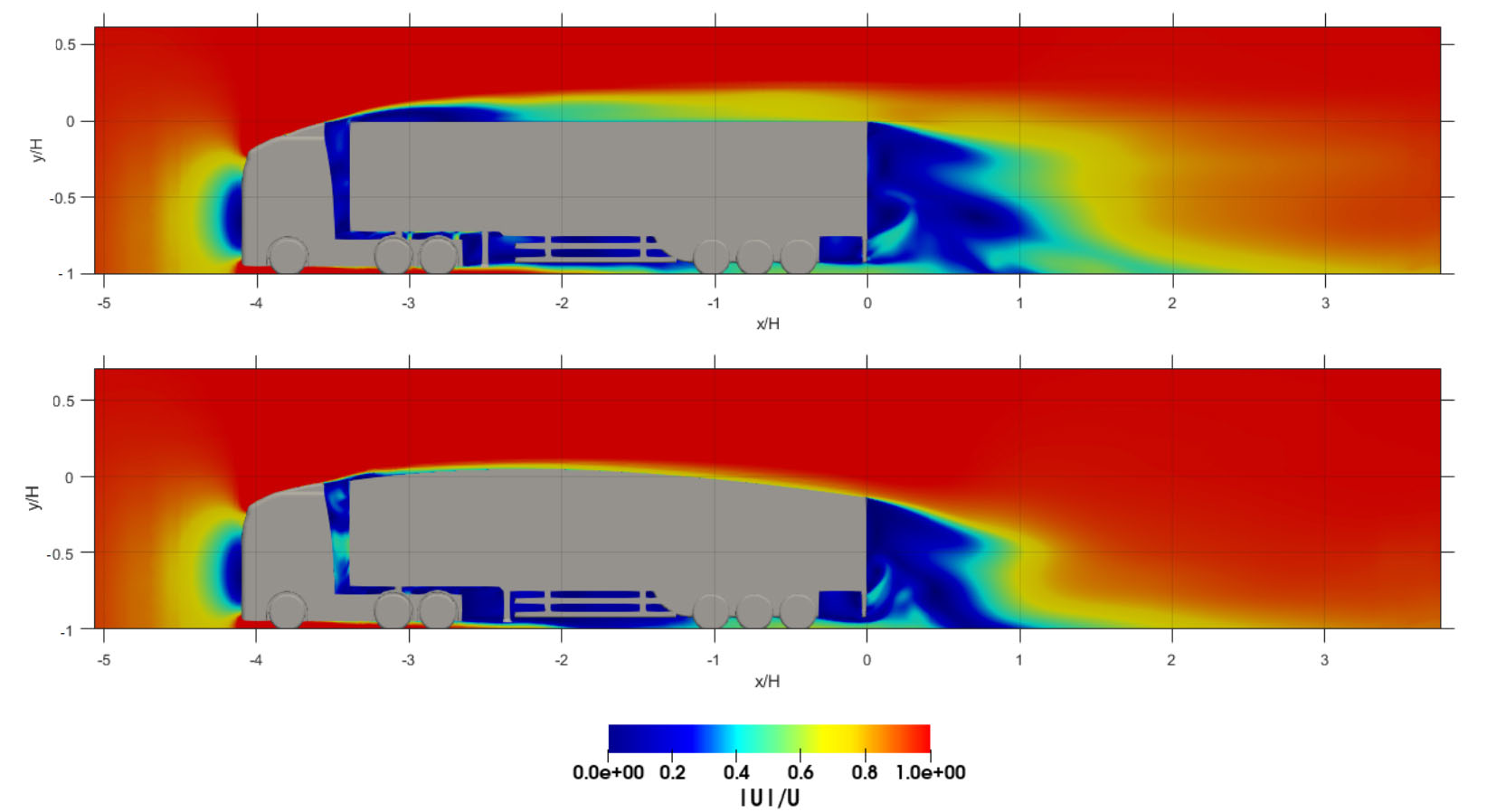

Main image: normalised velocity

A new study from the University of Surrey has investigated whether the Don-Bur Teardrop trailer works and, if so, why? Comparing a Teardrop against a 4.1m high standard box van trailer, the project summary confirmed an aerodynamic drag reduction of 15%† and an expected reduction in fuel of 7%. At today’s bulk diesel prices, that would save an operator £2,183†† and also result in a 6.3 tonne reduction in CO2 per annum.

Previously, Don-Bur had only collated real-world proving ground and operator trial results; however, numerous variables can skew those results, prompting a more scientific approach. Titled “Could Teardrop Trailers Reduce Drag on Articulated Lorries?”, the University of Surrey project report was carried out by Andrei Stylianou and used SimScale Computational Fluid Dynamics to carry out the analysis. The purpose of the study was to ‘investigate the drag reduction capabilities of an articulated lorry hauling a teardrop trailer as opposed to the conventional box trailer’ and highlights some interesting results.

Contrary to some previous beliefs, the study uncovered that the key mechanism behind the Teardrop’s success was “keeping the main flow attached to the roof of the trailer and directing the upper shear layer downwards towards the ground. This effectively reduces the size of the wake by improving velocity recovery.”

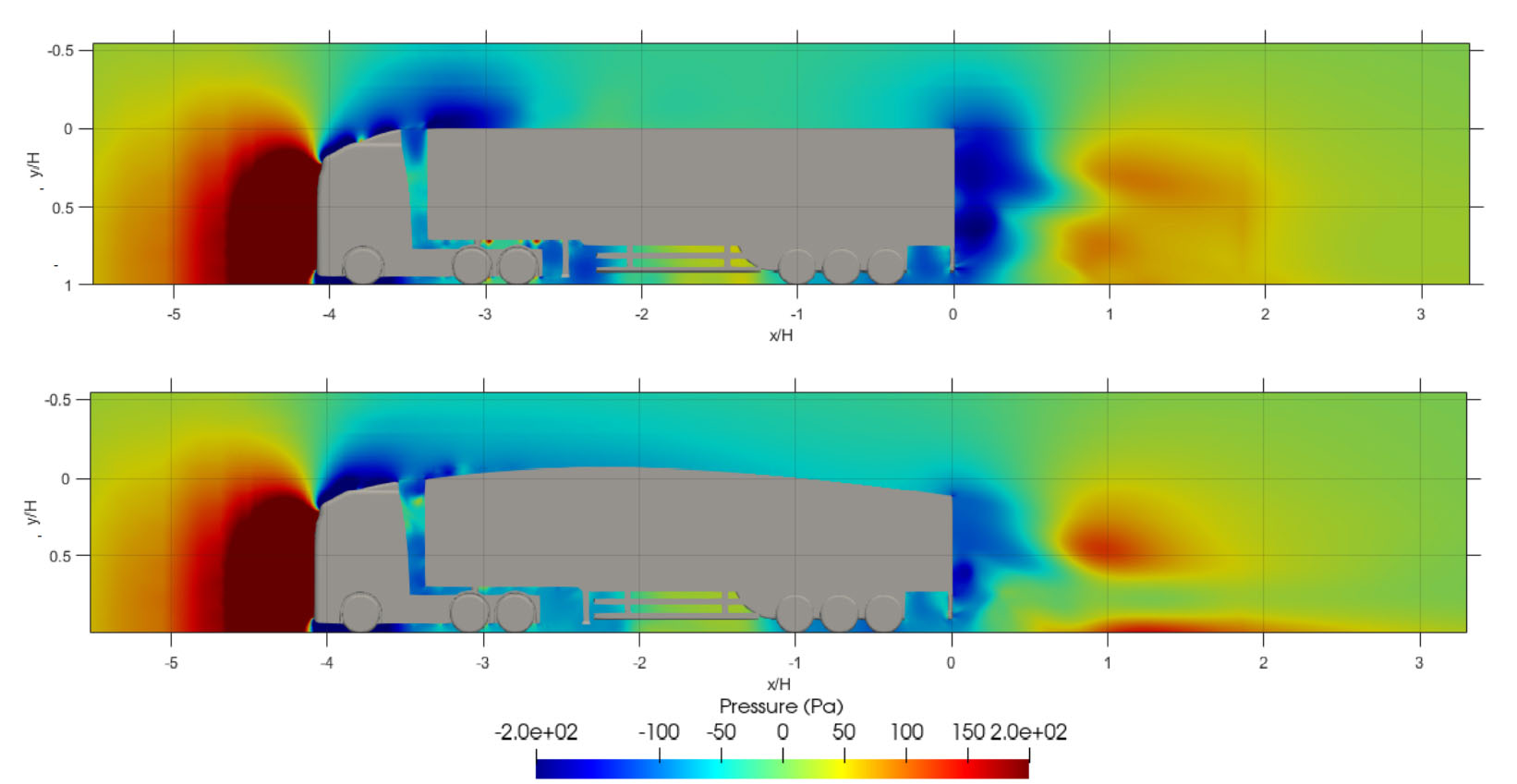

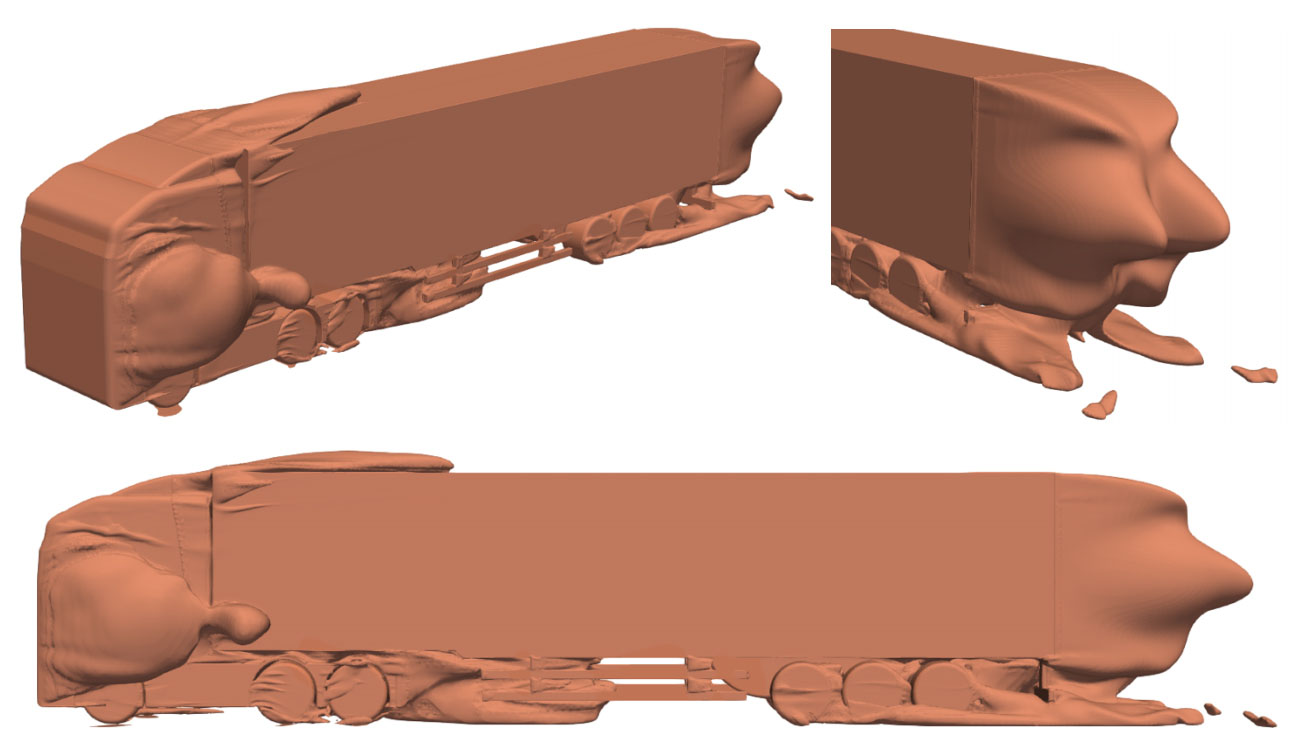

Above: pressure distribution

“Qualitative analysis of pressure distribution showed a significantly larger pressure recovery in the wake region of the Teardrop trailer, responsible for the drop in pressure drag, and hence the drag coefficient, when compared to the conventional trailer.” For a standard trailer, the length of absolute wake was 3.03m whereas the Teardrop only had a wake length of 2.09m.

Additionally, the project simulated additional roof camber (curved slope) variations to see if the saving could be improved but, after analysis, it was found that the drag reduction capabilities of the Teardrop trailer appeared independent of the curve.

The study serves to cement the effectiveness of the Don-Bur Teardrop trailer and helps to underpin the logic behind ROI calculations. Richard Owens, marketing manager from Don-Bur comments, “Unless backed by proven results, it is often counter-intuitive to invest money to save money. It simply feels more natural to spend less. We feel, however, that this independent scientific study goes a long way to providing the proof required to encourage further investment into this award-winning green technology.”

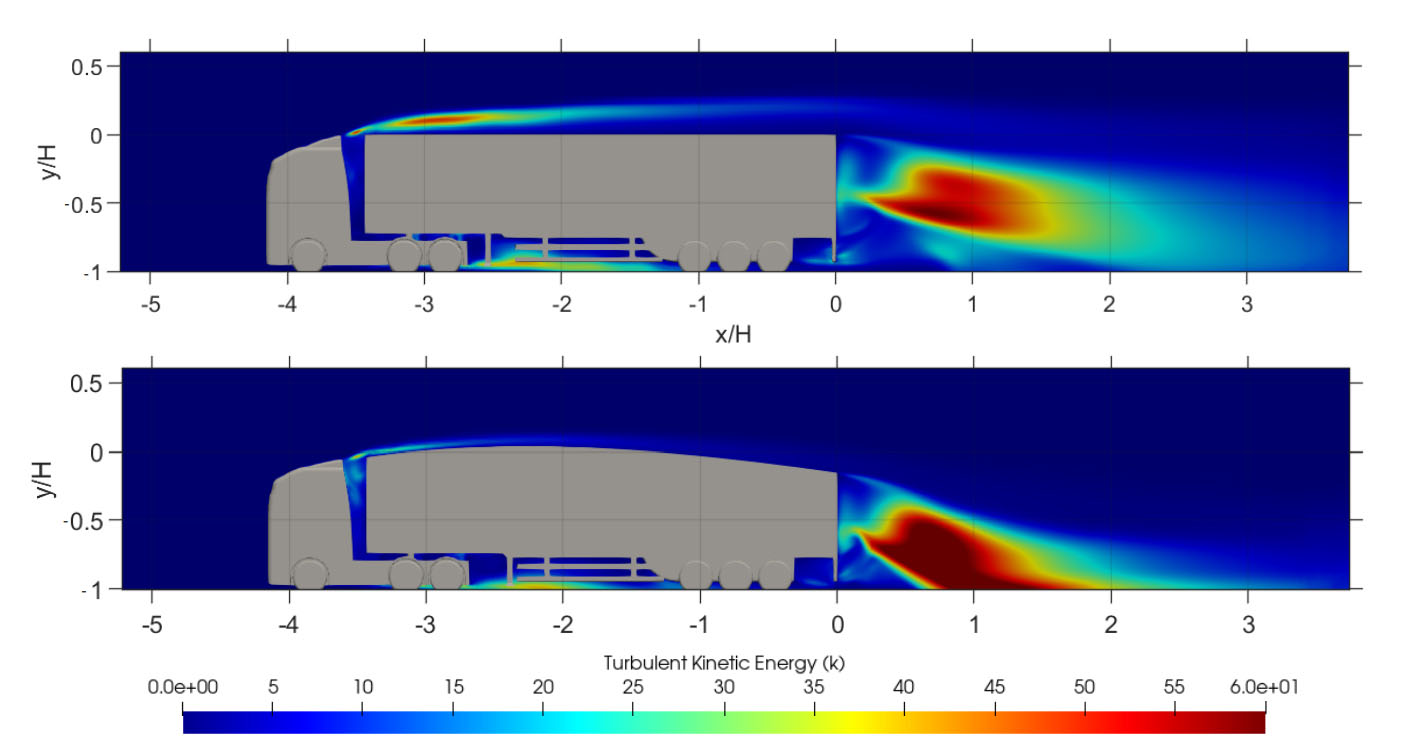

Below: turbulent kinetic energy

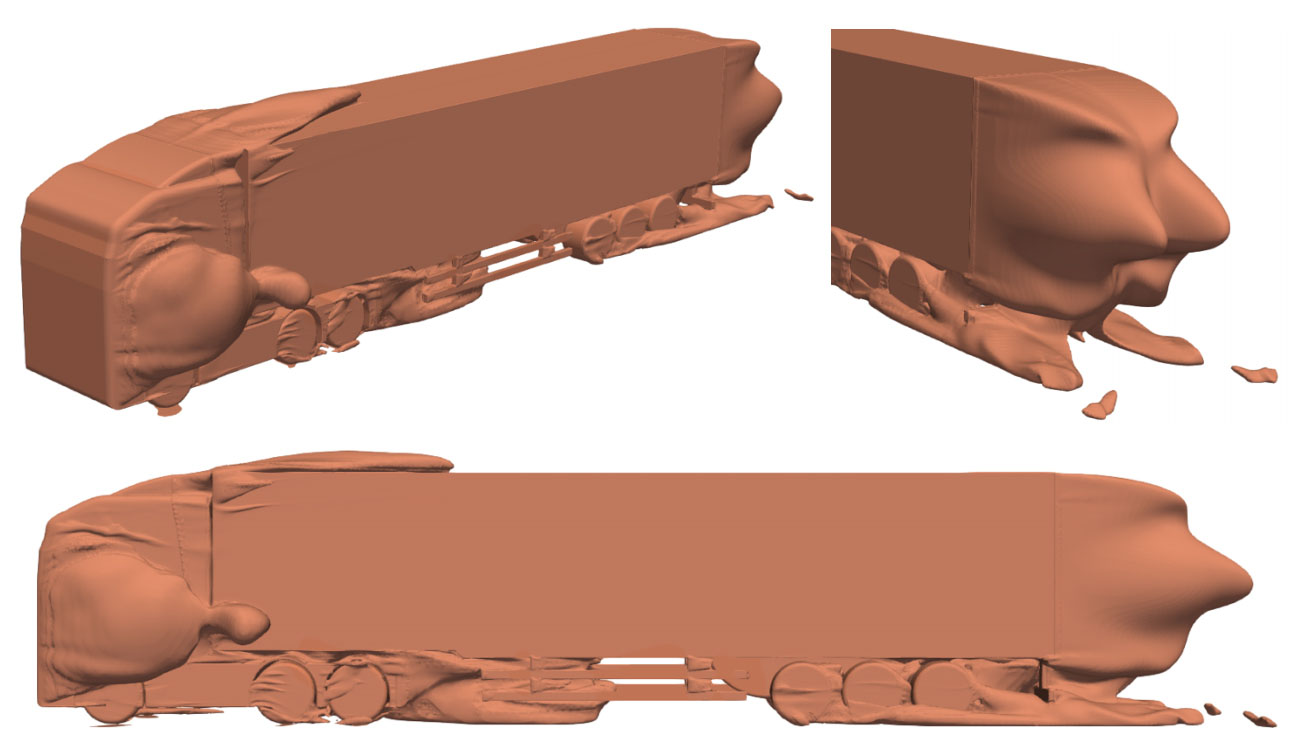

Below: negative pressure zones comparing standard trailer versus Teardrop trailer

†Final results showed a reduction in the coefficient of drag (CD) from 0.58 to 0.49.

†† Calculation based on a 4.3m high Teardrop trailer (with an average fuel consumption of 10.7mpg) compared with a 4.1m high standard trailer (with an average fuel consumption of 10mpg) travelling 80,000 miles with a bulk diesel price of 91.74 ppl.

Published: Wed 26 May 2021

Updated: Thu 11 Apr 2024

Author: Richard Owens

Published by: Don-Bur