An ISO neck profile refers specifically to the front end geometry of a semi-trailer, particularly the skid plate length, chassis angle behind the skid plate, and the position of the landing legs, as defined within the broader scope of ISO 1726-1. The term "ISO neck" is a common shorthand used in the industry, but it only represents part of the full ISO-defined envelope governing tractor-trailer compatibility.

The full ISO 1726 standard sets out a wide range of dimensional requirements to ensure safe coupling and articulation between a trailer and any standard tractor unit. This includes not just the trailer neck, but also the critical clearance zones between the rear of the tractor cab and the front bulkhead or equipment on the trailer, helping to prevent mechanical fouling during tight manoeuvres.

- Safe articulation with standard tractor units

- Consistent swing clearance behind the cab

- Reliable interchangeability across mixed fleets

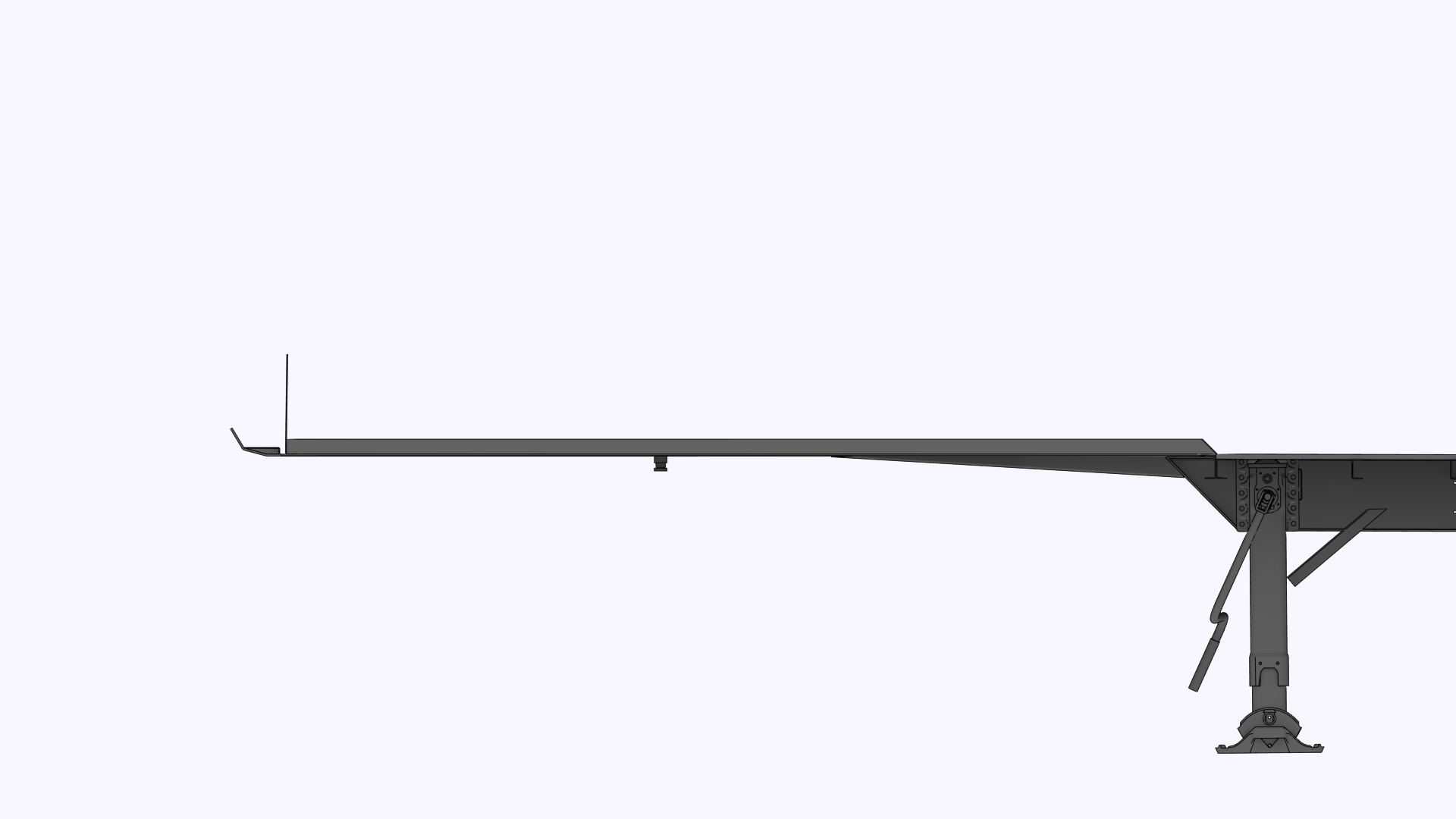

The standard defines a rear swing clearance radius of 2.3 metres from the kingpin, which any trailer features (such as landing legs or bulkhead fixtures) must stay outside of.

What Does ISO 1726 Actually Specify?

ISO 1726-1 outlines the standard dimensions and clearances that must be maintained between a tractor and trailer. While it refers to the position of the skid (rubbing) plate, it does not prescribe a single fixed vertical height for it. In practice, the vertical position — or kingpin height — varies considerably depending on regional standards and trailer design. It includes:

- The vertical and horizontal location of the trailer skid plate

- A defined swing clearance envelope around the kingpin

- Reference points for allowable kingpin positions within that envelope

- Maximum permitted intrusion zones for trailer chassis and components

- Mounting dimensions and tolerances for the kingpin and skid plate

- Guidelines for avoiding contact between the rear of the tractor cab and front of the trailer, including wind deflectors, bulkheads, refrigeration units or hose trays

The standard does not dictate a single fixed kingpin setback or vertical skid plate height. Instead, it defines zones within which the kingpin must fall to ensure clearances are maintained.

In the UK, kingpin heights are typically around 1250mm, but in continental Europe, trailers often run much lower — sometimes as low as 950mm — to suit different operating environments and vehicle designs. This variation affects not only compatibility with tractor fifth wheel heights but also the design of the trailer neck to achieve the required load space while maintaining swing clearance.

Standard Kingpin Positions

Although ISO 1726 permits some flexibility, most full-length trailers in the UK and Europe are built with the kingpin set at 1600mm from the front of the skid plate. This has become the de facto standard because it:

- Provides sufficient swing clearance

- Ensures legal weight distribution across axles

- Maintains compatibility with 4x2 and 6x2 tractor units

Shorter Kingpin Setbacks for Urban and Brewery Trailers

Certain specialist trailers, such as those used for urban deliveries or brewery work, use shorter kingpin setbacks — typically between 900mm and 1200mm.

- Allow for improved manoeuvrability in confined areas

- Help reduce overall vehicle length

- May limit compatibility with some tractor units if not carefully matched

Urban trailers present a unique challenge when it comes to ISO swing clearance. Because the 2.3m rear swing radius still applies — even on shorter vehicles — the landing legs often end up positioned closer to the geometric centre of the trailer. This increases the risk of see-sawing or instability during loading and coupling, especially on uneven ground.

By shortening the kingpin depth, the landing legs can be moved further forward, closer to the trailer bulkhead. This helps ensure more stable ground contact, improves load distribution during coupling, and supports better handling on ramps or docks.

While still compliant with ISO 1726, these adaptations are highly application-specific and should be engineered with care to maintain overall compatibility and legal conformance.

Electric Tractor Units: A New Compatibility Challenge

With the growing adoption of battery electric vehicles (BEVs), a new complication has emerged. Many BEV tractor units house battery packs or cooling equipment behind the cab, which intrude into the ISO-defined swing clearance envelope.

To maintain ISO-compliant clearance, operators may be forced to move the tractor's fifth wheel further rearward, which introduces new challenges:

- Increased overall vehicle combination length, potentially breaching the 16.5m legal maximum

- Difficulty achieving the required 5.3m inner / 12.5m outer turning circle

- Altered axle load distribution, with increased weight on the drive axle

- Reduced compatibility across mixed fleets if fifth wheels are fixed

In other words, the trailer doesn’t need to change — but tractor configuration becomes more critical. Operators adopting BEVs must ensure proper swing clearance is maintained to avoid illegal or unsafe combinations.

Can You Use a Non-ISO Neck Profile?

Yes — but only for specific applications.

Some bespoke trailers, such as ultra-low floor double decks or urban delivery bodies, are designed with non-standard neck profiles to maximise internal height or reduce overall length. These can:

- Improve operational efficiency

- Meet niche customer needs

- Require dedicated tractor units

However, they will generally fall outside the ISO 1726 compatibility envelope, which can limit flexibility.

At Don-Bur, we offer both ISO-compliant and custom neck profiles, balancing regulatory requirements with real-world application needs.

We’d love to hear from you – get in touch today!