What Is a Demount Body?

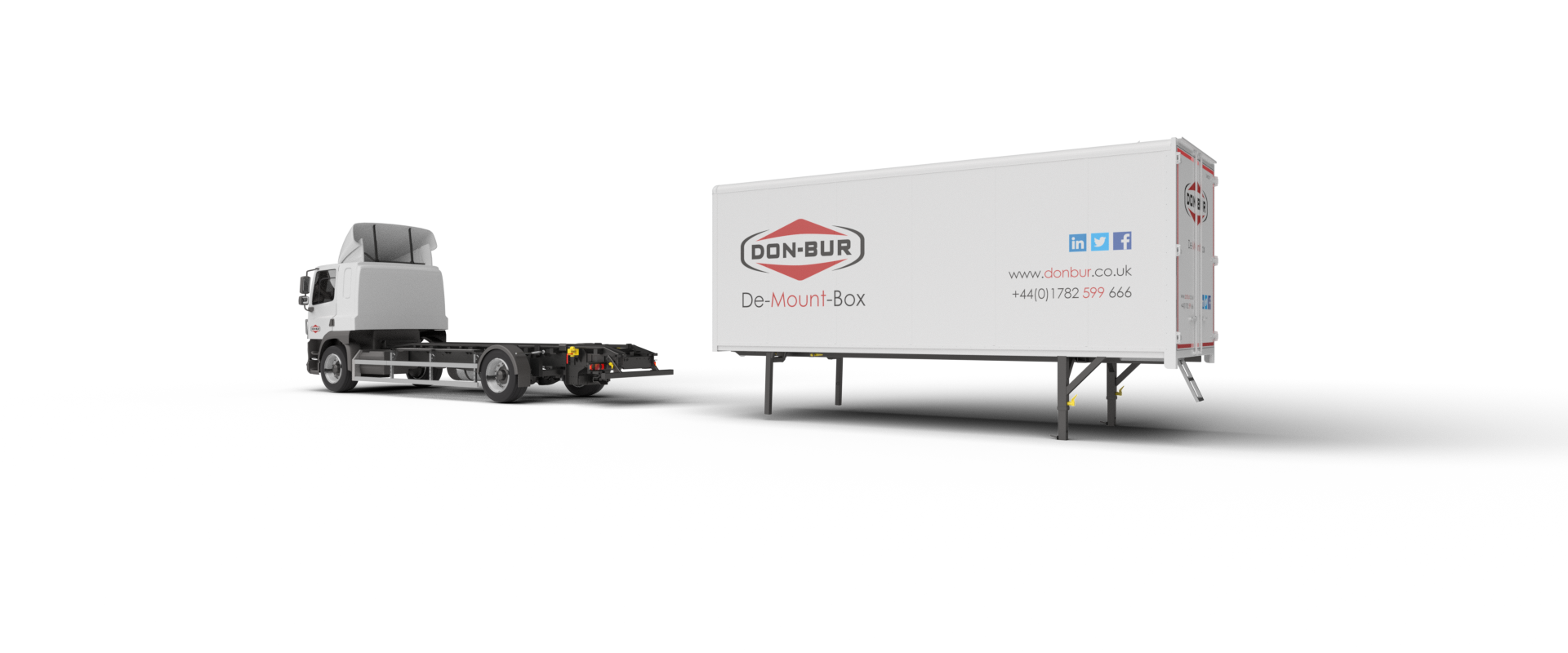

Sometimes referred to as a Swap-Body or Demountable Bodywork, a demount refers to bodywork that can be simply detached/re-attached from the chassis cab or draw-bar trailer unit and stand independently on integral landing legs.

We’d love to hear from you – get in touch today!